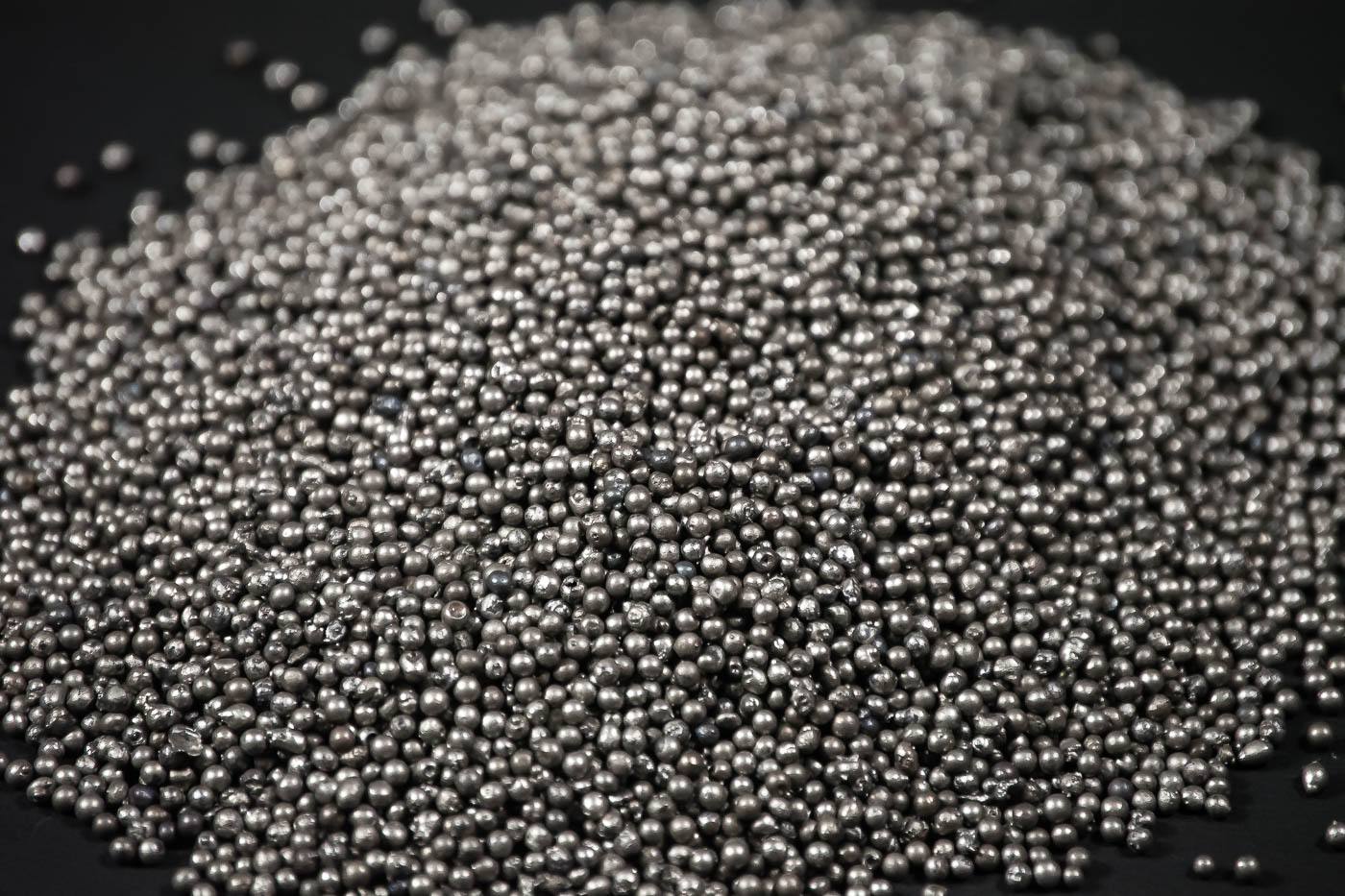

Silicon carbide Grit

| Brand Name | Granite Engraving Machine |

| Material | Silicon Carbide |

| Form | Powder |

| Hardness | 9.5 Mohs |

| Specifica Gravity | 3.2 |

| Melting Point | 2250 Degree |

| Packaging Size | 25kg, 50kg, 1 ton |

| Packaging Type | Wooven Gunny Bags |

- Silicon carbide abrasive is extensively used in metalworking and machining applications.

- Silicon carbide abrasive is essential in the production of ceramics and glass.

- It is used for cutting, shaping, and finishing ceramic components, such as tiles, bricks, and refractory materials.

- Silicon carbide abrasive is widely used in the construction and stone fabrication industries.

Silicon Carbide grit, is a very rapid, very hard abrasive. It is typically black in color. It is often used in blasting applications where the workpiece would be brazed after blasting. The utilization of Silicon Carbide grit abrasive paper is the most effective and useful procedure for granulating metallic metallographic examples. Although numerous characteristics of silicon carbide grit are promptly accessible, just the silicon carbide grit powder gives the most steady outcomes and most noteworthy granulating rates. Silicon carbide powders are handled at higher temperatures than lower-quality silicon carbide powders.

Along these lines, the silicon carbide grit powders acquire a more complete response between the silica and carbon segments. The subsequent gem structure is a hexagonal-rhombohedral gem structure with a hardness of roughly 2500 HV. This gem structure makes the silicon carbide grit powder an ideal abrasive for cutting and granulating in light of its high hardness and sharp edges. Silicon carbide grit is likewise to some degree fragile and along these lines cuts effectively to deliver sharp new edges. The subsequent Silicon Carbide grit abrasive with rapid involvement of shot blasting machine is a fantastic abrasive for expanding cutting rates while limiting surface and subsurface harm. For metallographic planning, Silicon Carbide abrasives are applied or covered onto abrasive pounding papers. To build the solidness just as to improve the capacity to eliminate utilized papers, a slim mylar film backing is clung to the Silicon Carbide grit paper. Silicon Carbide grit abrasive paper is accessible taking all things together in regular grit sizes going from 60 grit to 1200 grit.

Silicon Carbide Manufacturers in India

We are one of the industries top silicon carbide manufacturers in India. Depending on the specific needs of our clients, we offer silicon carbide in a variety of forms, including powder, grains, plates, and bars, as well as in different grades and sizes. We provide our clients with professional advice on how to handle and use silicon carbide as a material since we are skilled silicon carbide producers. The silicon and carbon compound known as silicon carbide is created and supplied by us. Due to its special qualities, including excellent thermal conductivity, minimal thermal expansion, high strength, and hardness, silicon carbide has a wide range of industrial uses. Along with being cost effective silicon carbide is also an excellent alternative of vast series of other abrasives such as steel grit, steel shots, and many others. As one of the top silicon carbide manufacturers in India, we put the needs of our clients first. We listen to their comments and strive to make sure their products meet or surpass their expectations.

Silicon Carbide Price Per Ton

Silicon carbide price per ton is more than reasonable given the variety of applications that the highly abrasive material may be used for. Being a Leading silicon carbide manufacturer in India, we supply silicon carbide to a range of sectors, including semiconductors, electronics, automotive, and aerospace. A variety of uses for silicon carbide in the alternative to cut wire shot include cutting tools, refractory materials, abrasive blasting, and high-temperature applications. Silicon carbide price per ton in India is, therefore, more than inexpensive and pocket-friendly due to the product's versatility. In India, we directly provide affordable silicon carbide prices per kilogram. As one of India's leading silicon carbide manufacturers, we have effective manufacturing practices that minimize waste and cut costs without compromising quality. We maximize our resources and streamline our operations using lean manufacturing principles.

Silicon Carbide Abrasive

One of the strongest abrasives, silicon carbide has a Mohs hardness of 9.5, making it perfect for grinding and cutting applications. Silicon carbide abrasive is the best choice for usage in demanding circumstances when abrasive wear is an issue because to its remarkable wear resistance. A great abrasive for increasing cutting speeds while reducing surface and subsurface damage is the next Silicon Carbide grit abrasive. Silicon Carbide abrasives are coated or applied to abrasive pounding sheets for metallographic planning. A thin mylar film backing is adhered to the Silicon Carbide grit paper in order to increase both the solidity and the ability to remove used sheets. It is harder than aluminum oxide grit and is close to the hardness of diamond on the Mohs scale. These characteristics make it an extremely aggressive media.

Due to silicon carbide's high thermal conductivity, it is possible to effectively dissipate heat during grinding or cutting, which reduces the risk of overheating and damaging the material being worked on. Since silicon carbide is chemically inert and doesn't react with many chemicals, it may be employed in a wide range of applications. The sharp edge of silicon carbide abrasives allows for aggressive material removal, making them ideal for cutting and grinding hard materials including metals, ceramics, and composites.

Sand Blasting Machine

Quick Enquiry