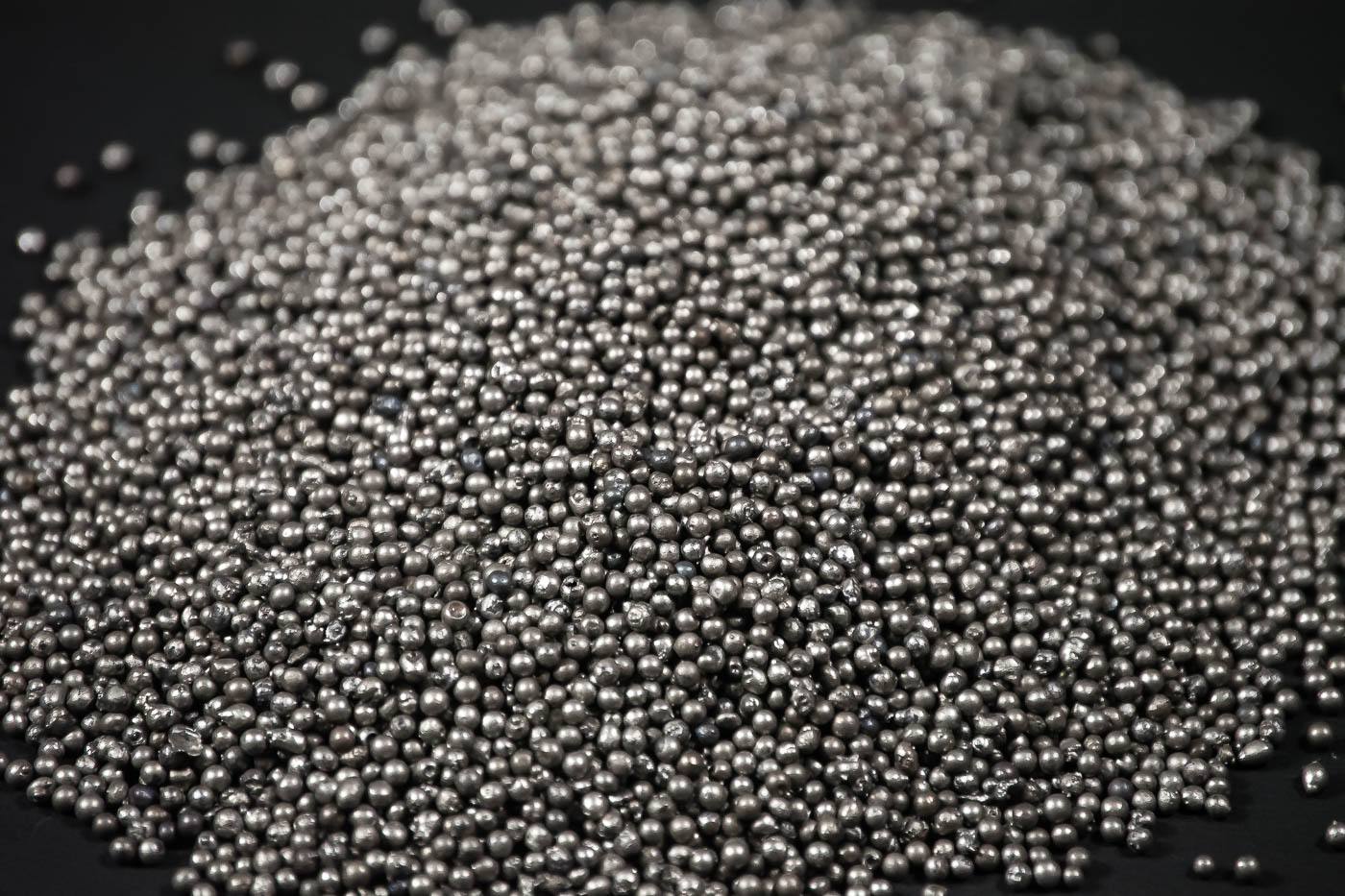

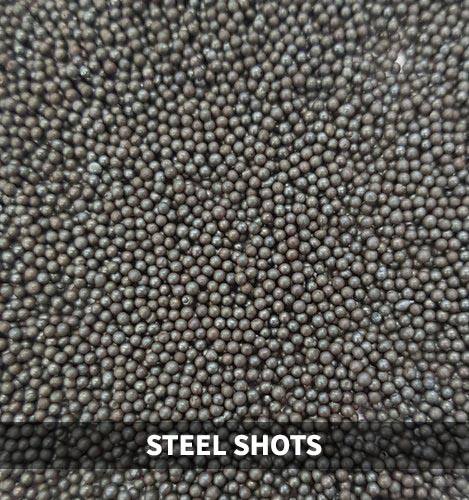

Steel Shots

Steel Shots are spherical or round particles like a circular ball made of molten steel through an atomization process; these cast steel shots are available in different sizes & hardness. Steel shots are made from steel scrap. It is made in an electric furnace. First, the steel scrap is melted in the furnace then it is atomized/converted into the shot by a water jet. Steel Shot is durable in nature due to its low friability, the impact of blasting actually further tempers the shot so that its hardness increases over time, allowing the media to deliver consistent, repeatable performance over thousands of cycles. Granite Engraving Machine provides all steel shot sizes and grades. We are one of the best steel shots manufacturer's in India at a low price with the best quality

Steel Shot is an extremely low breakdown rate; even no dust is produced in the manufacturing process. Delivering high-impact energy and fast cleaning rates, Steel Shot is used to produce a very bright finish. The grade or size of the steel shot helps in determining the finishing achieved on the surface of the metal. Steel shot blast media with a small size will result in a smoother and more polished surface. Steel shots in India with large sizes will clean more aggressively but produce a rougher surface. Both pneumatic machines and wheel shot blasting machine can be used to accelerate the steel shot onto the blasting surface. Due to its hardness and density, it can be recycled 3000 times before replacement. In the manufacturing of steel shots, a minimal amount of dust is created in the blasting process. Cast steel shots abrasives are essentially used to clean metal surfaces and parts like desanding and cleaning foundry castings, descaling metal sheets, and surface preparation before thermal spray gun coating.

Steel Shots Manufacturer

We are one of the top steel shots manufacturer and exporters foundries of steel shots in India. By melting steel scraps in a furnace and then pouring the molten steel into a ladle, we produce high-quality goods. This ladle has been slanted to allow the falling of molten steel into a cooling tank. The water jet that strikes the falling molten steel causes it to shatter into small drops. After they reach the cooling tank, they start to descend quickly and solidly.

Granulation or atomization is the name of the process used to create this product. In order to maintain the quality of the steel shot that has been made, our engineers continue to monitor the process and add Ferroalloys. To manufacture semi-finished shots to the demands of our customers, heat treatment is applied to them.

Steel Shot Blasting

The best cleaning method before forming, shearing, rolling, painting, or galvanizing is blast cleaning. Shot blasting is a method for cleaning, descaling, and rust removal from items. Similar to sand blasting machine operation, parts are "sprayed" with a shot to restore their former bright metallic appearance. A homogeneous shine, suited for lubricant adhesion, covers the recovered surface.

By removing the abrasive mill scale, blast cleaned steel lowers wear on shears, punches, and roll-formers. This might enable instant painting. Moreover, the necessity for post-fabrication cleaning is removed by blast cleaning.

Steel Shot blasting involves using one of many different kinds of shots to damage a material's surface. Generally, this is done to remove something from the surface, like scale, but it is occasionally done to give the object being shot blasted a specific surface, like the rolls used to create a 2D finish. Sand, tiny steel shots of different steel shot sizes, granules, etc. can all be used as steel shots.

Steel shot price depends on the steel shot sizes, grade, and hardness of steel shots in India. our steel shot price is very low compared to others. Steel shot price also leans on the quality, and quantity of steel shot media.

Steel Shot Blast Media

Steel Shot Blast Media can be recycled between 2000 and 3000 times, which is a high rate. As a result, they produce less waste than other disposable abrasives. Steel shots media are three times tougher and less dense when compared to lead shots. We are the leading steel shots supplier & manufacturer of steel shot blasting media in India.

Steel Shot Sizes

| Steel Shot Grades | Steel Shot Sizes |

| S-930 | 2.4mm |

| S-780 | 2.00mm |

| S-660 | 1.70mm |

| S-550 | 1.40mm |

| S-460 | 1.20mm |

| S-390 | 1.00mm |

| S-330 | 0.850mm |

| S-280 | 0.700mm |

| S-230 | 0.600mm |

| S-170 | 0.425mm |

| S-110 | 0.300mm |

| S-70 | 0.180mm |

Steel Shots Application

Application of steel shots are used in:

- Steel Shot Blast Media For Automotive Industry

- Steel Shots For Aerospace Industry

- Steel Shot For Agriculture Industry

- For Construction Industry

- Steel Shots in India are used For Foundry Industry

- Steel Shot abrasive For Mining

- Steel Shot media For Shipyard

- Steel Shot blast media For Stone Cutting

- Steel Shot media For Office machines

- Steel Shot abrasive For Petrochemical Industry

Steel Shots Features

- Long-Term Stability

- Steel shots in India are Multipurpose

- High resistance to abrasion

- Faster cleaning and slower consumption

- Similar solidity

- Same stiffness

- Dimensional accuracy

- comply with the current global quality standards

Sand Blasting Machine

Quick Enquiry