Glass Engraving Machine

| Brand Name | Granite Engraving Machine |

| Workspace Area | 800 x 500 MM |

| Maximum Load | 20 KG |

| Spindle | 440 Valt |

| Packaging Type | Wood Box & Bubble Sheet |

| Delivery Time | 10-15 Days |

- Glass engraving machines are employed to add a personalized touch to gifts and awards.

- Glass engraving machines are used in the architectural industry to create custom-designed glass panels and partitions.

- Glass engraving machines are often used to create exquisite art pieces and decorative glass items.

- Glass engraving machines are utilized to create branded glassware for businesses such as restaurants, bars, and hotels.

Glass laser engraving machine has become popular. This advanced technology of glass engraving machine has been employed by businesses, designers, amateurs, and manufacturers to improve their glassware. Not only that, but they've successfully developed newer and better items while keeping high-quality craftsmanship with a glass engraving machine. We offer all the information you need, whether you're new to a laser engraving machine with a glass engraving machine or you're on your third or fourth machine. So read on to learn more about the laser engraving machine, how it works on glass, and what to look for when purchasing a laser for glass etching and branding. Glass items are incredibly diversified and exist in a wide range of forms and sizes. From glass tumblers to automobile windshields, our laser equipment can etch and engrave patterns. Our CNC laser engraving machine equipment for glass etching and engraving are exceptionally precise, which reduces mistakes, waste, and production delays. Glass has been a favored medium for artists, manufacturers, and bespoke designers alike as customer demand for glass items grows

If you work with glass materials or goods, the CNC laser equipment for glass etching and engraving from AP Lazer will benefit you much and this collectively sums up with a glass engraving machine. Our glass engraving machine has an open-architecture design that allows you to upgrade functions and customize features to match your individual production requirements. Our larger versions also feature a flexible design: the laser top may be removed, allowing you to etch and engrave glass items that are larger or broader than the area available. As a consequence of our market research, our glass engraving machine are very configurable. Because our technology can precisely determine the proportions, forms, engravings, and marks they wish to add to glass materials, they may utilize our technology.

The laser machine may also operate without continual human monitoring because it is computer-assisted. Our glass engraving machines are highly adjustable as a result of our market research. They can utilize our technology since it can exactly define the proportions, shapes, engravings, and markings they want to apply to glass materials. Because it is computer-assisted, the laser machine may function without constant human supervision. The ultimate effect of laser etching glass is frequently an appearance of luxury and refinement. When laser etching glass or crystal, the result is a frosty mark that stands out but is smooth to the touch.

Glass engraving machine exporters for sale in India

We collectively provide glass engraving machine for sale in India and hence it can be stated that we are a leading glass engraving machine exporters in India. On glass and mirror items, a number of laser engraving techniques may be employed to create unique designs. When etching glass, one thing to bear in mind is that the laser must be able to dissipate heat. Many laser engraving on glass techniques is dependent on how heat is dispersed and attempting to manage the glass's surface temperature while the laser is operating. Here's a rundown of some of the most often used glass engraving techniques: Laser etching using a dampened paper towel the use of a moistened paper towel over the engraving area is a good approach for glass engraving. To begin, dampen a paper towel and lay it over the glass as per such techniques we are a leading glass engraving machine exporters in India itself which have their impact over

Glass engraving machine price in India

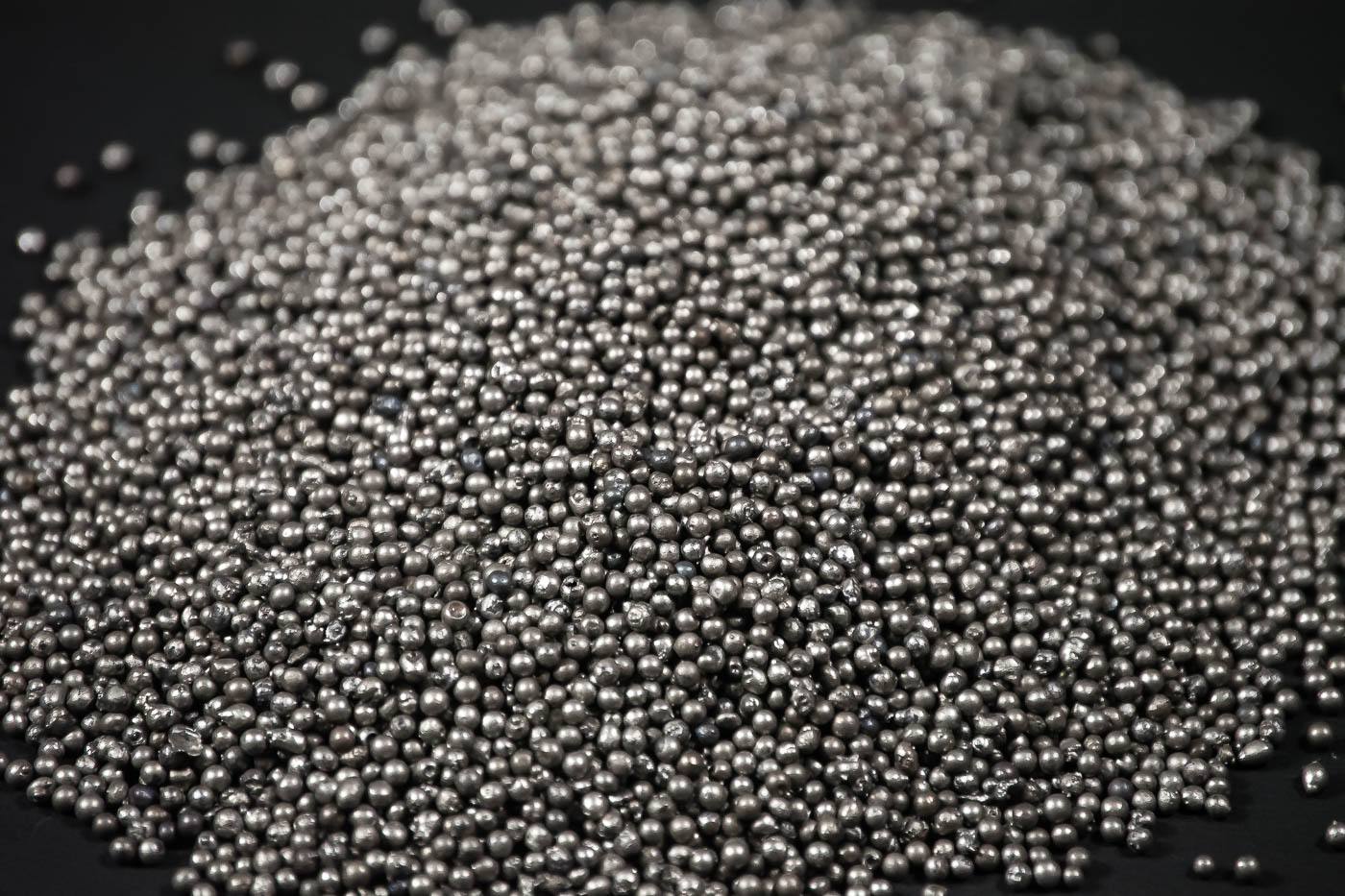

We are a leading name amongst the leading glass engraving machine manufacturer along with this we collectively manufacture a vast range of products such as the world's largest maker of glass bead blasting, as well as a comprehensive selection of products at affordable prices for export from India. as per the quality leading glass engraving machine manufacturer set the glass engraving machine price as per various regulatory factors of prices. Abrasive grits, copper slag, aluminum oxide, steel shots, cut shot blast, plastic media, quartz sand, abrasive garnet sand, and many more products are also manufactured and exported by us. As a result, we provide a diverse selection of products to meet the needs of many industries. Application tape is another technique for laser engraving that prevents the formation of rough areas where the glass is being etched. Application tape can prevent air bubble development and overlaps in the same way as a moistened paper towel does. The main difference between using a moistened paper towel and using application tape is that the application tape will produce a grey outcome rather than a white engraving. This is a realistic choice to explore for many applications since it is beneficial for some projects. Without the use of any materials, engrave (dampened paper or application tape) Without using one of the above ways, the CNC laser engraver may still work on any glass or mirror product.

Glass engraving machine manufacturers in India

In India, we are a leading glass engraving machine manufacturers in India This set includes a four-axis engraver with a built-in drill, a mill, and a lathe. The machine completely supports MACH3, Entia, TYPE CNC, and other commonly used software systems. It may be etched on softwood, PVC, acrylic, plywood, and other materials. For iron, copper slag, and steel, the maximum engraving depth should be less than 2mm. Every etching depth should be increased by 0.1mm by adding water to avoid abrading. It's sturdy, performs well under pressure, is accurate, and produces smooth, uniform curves.

A marble engraving machine can engrave silver, gold, copper, brass, and bronze. It comes in 15 different ratios, ranging from 2 to 15.

Glass Processes in Two Types

- Engraving Glass is the technique of vaporizing a thin layer of glass to create a hollow or void in which the pattern may be seen.

- Etching Glass - The physical process of removing the top layer of glass by 0.001′′, gives the glass a frosty, somewhat opaque appearance.

Sand Blasting Machine

Quick Enquiry