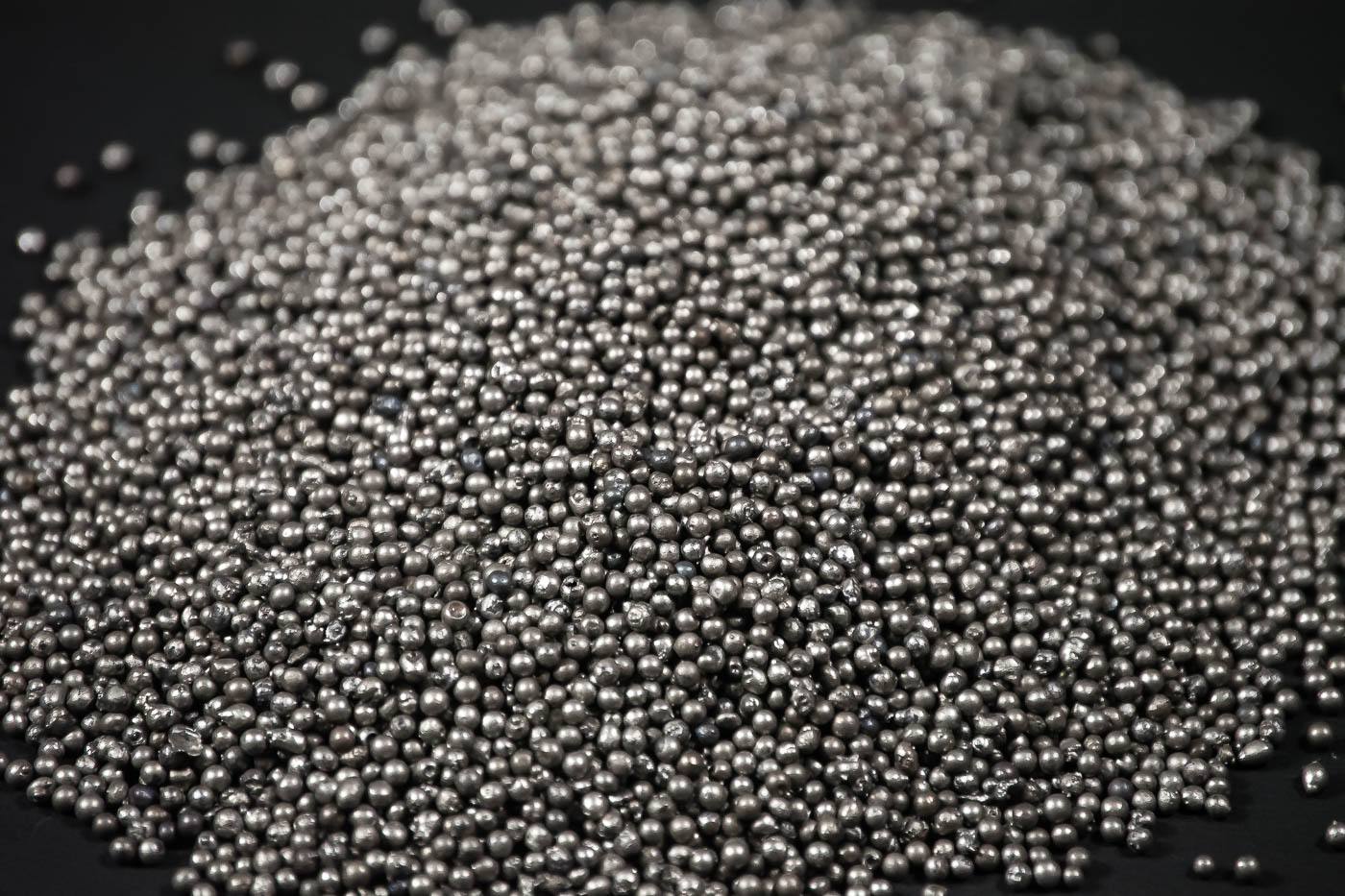

Mild Steel Shot

Mild Steel shot refers to spherical grains made from molten steel through an atomization process, available in several sizes and hardnesses. These cast steel shots are available in different sizes & hardness. Steel shots are manufactured from steel scrap.

Why Mild steel shots are used for?

Mild Steel retains less energy and may not kill birds cleanly at the same ranges. Steel with equivalent weight and shot size contains more pellets than lead, making loads that contain more shot than necessary. Compensate for the lighter weight by employing a shot one or two sizes larger than the lead shot size.

Classification of mild steel shots

|

Basis |

Steel Shots |

Solid Steel Shots |

|

Raw Material |

Basis raw material has lower physical property & composition |

Raw Material is of exact composition without any material defect (blow holes, porosity, shrinkage, etc.), and wear out nominally during its use. |

|

Hardness |

Various a lot(40-50 HRC) |

Marginal variation(50-52 HRC) |

|

Dust |

High Dust Generation |

No dust generation |

|

Grain Size |

Varies a lot |

No variation |

|

Performance Consistency |

Lower consistency as size & hardness varies a lot |

High consistency as size & hardness have no variation |

|

Time Consumption |

Higher Consumption |

Reduces time for shot blasting |

|

Inventory Cost |

Higher inventory due to high consumption, more money & space required |

Saves on inventory cost, eventually reducing operating cost |

Different sizes of mild steel shots

|

Solid steel shot designation (mm) |

Equivalent cast shot size |

|

0.80 |

A-330 |

|

1.00 |

A-390 |

|

1.20 |

A-460 |

|

1.40 |

A-550 |

|

1.60 |

A-660 |

|

1.90 -2.00 |

A-780 |

Chemical Composition of Mild Steel Shots

|

Carbon |

0.60% to 0.80% |

|

Manganese |

1.10% max |

|

Sulphur |

0.045% max |

|

Phosphorous |

0.035% max |

|

Silicon |

0.35% max |

|

Hardness |

50-55 HRC |

Industrial Applications

- Shot Peening

- Shot Cutting

- Cleaning

- Surface Preparation

Sand Blasting Machine

Quick Enquiry