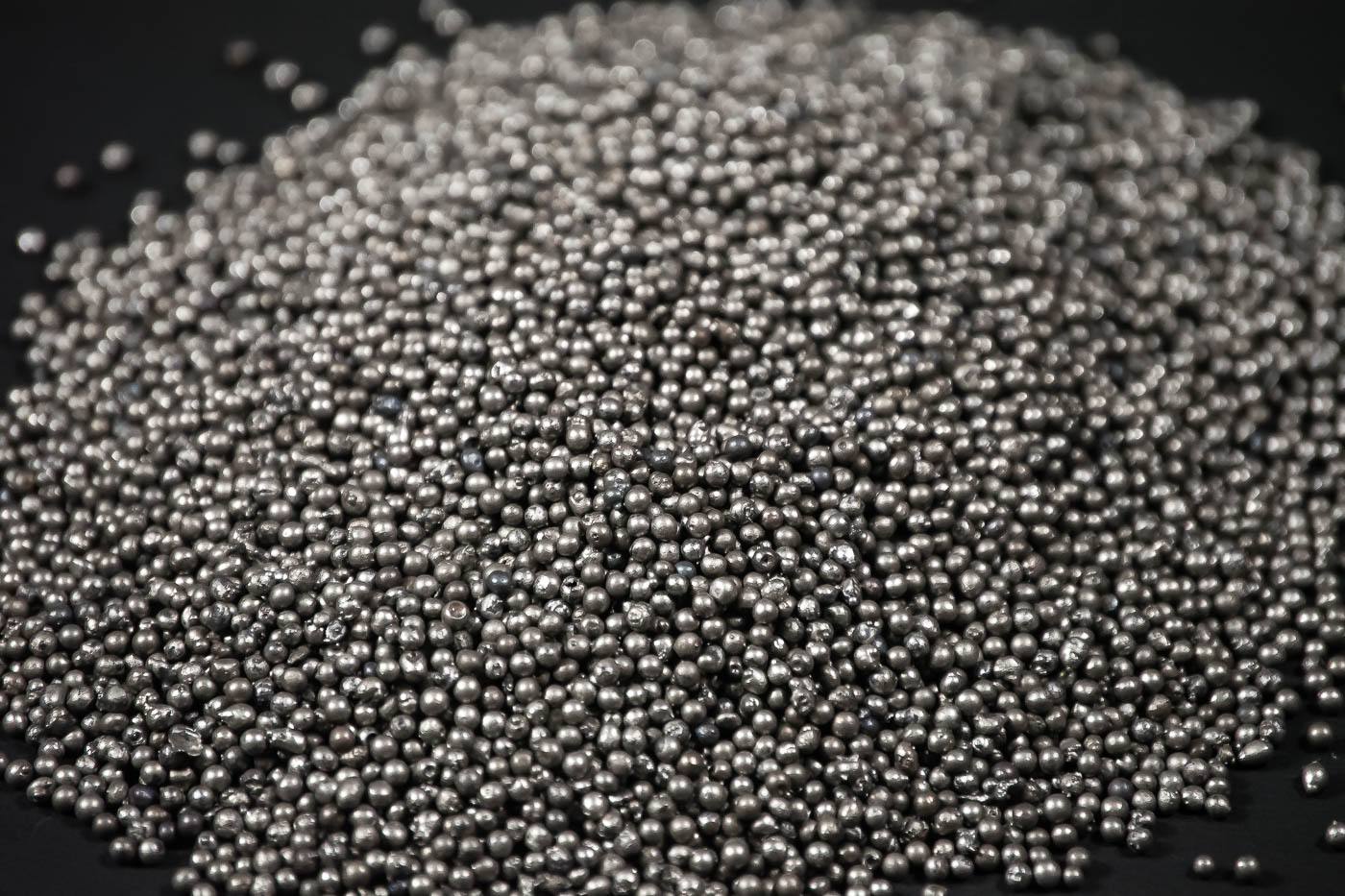

Stainless Steel Shot

Stainless Steel Shots

The Stainless Steel Shot or SS shot is used for the preparation of metal surfaces by shot blasting before any other media coating, removal of sand from castings, descaling of steel strips, etc. It has a wide range of applications in different industries like automotive, blast/paint contractors, steel fabricators, etc it is best for peening applications to clean, smooth & smooth finish surfaces. The best thing for which it is used in large numbers is its recyclability rate; it can be used various times before replacement due to its hardness and density. This stainless steel shot generates a low amount of dust in the blasting process.

Stainless steel shot is used in many applications where non-rusting materials such as aluminum, zinc, brass, bronze, etc. are blasted. Stainless steel shots are of grain size which makes it perfect for cleaning, de-burring, hardening, and surface finishing of all types of castings, forgings, profiles, wire and welded structural parts, without the possibility that rust could discolor the bright surface due to ferritic dust generated in the process. Stainless steel shot differentiates itself by having a high percentage of spherical grains and by its compact nature. This provides low consumption, high performance, and low machine wear as the end result.

Using Stainless steel shot on a smooth and textured structure brings out the stones unique appearance, and the possibility of developing unsightly rust spots on the surface of blasted concrete and granite stones due to the remains of ferritic particles is ruled out.

Application of stainless steel shot

- Blast cleaning, deburring

- Surface finishing

- Surface-improvement

- All types of aluminum castings and

- die castings

- Non-ferrous metals and special alloys

- Concrete and natural stones

Advantages of Stainless steel shot

- Great durability

- Has small blasting times

- Gives bright appearance

- Results in rust-free surfaces

- Reduced wear of blast cleaning equipment

- Has low waste disposal costs

- Is a dust-free blasting process

Sand Blasting Machine

Quick Enquiry